Jemena takes delivery of SEA electric truck with cherry picker platform

The Jemena Electricity Distribution Network in Victoria has just received its first electric Hino truck with Elevated Work Platform (EWP) in Australia.

Made by Melbourne’s SEA electric in collaboration with Niftylift, the elevated work platform truck will help reduce the operational carbon output of Jemena, which delivers electricity in Victoria and pipes gas in Victoria, ACT, Queensland and NSW, by 30 tonnes per year.

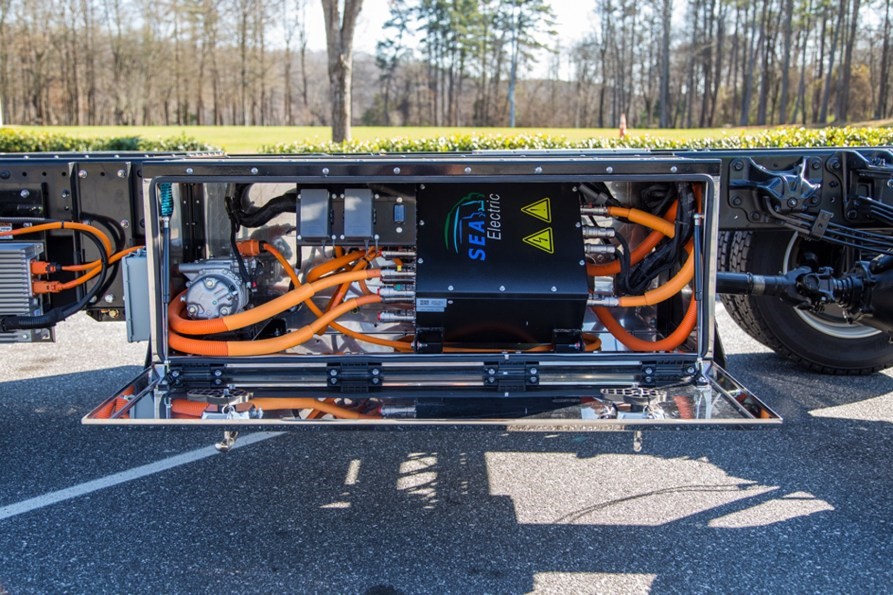

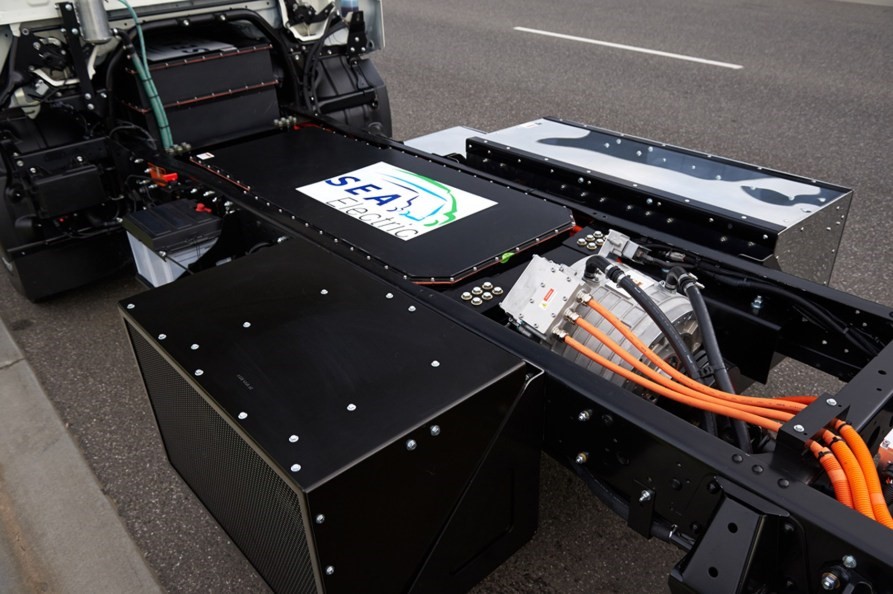

To make the truck, SEA electric took a Niftylift diesel cherry picker and converted it using one of its patented electric drivetrains and equipped it with a 138 kilowatt hour battery.

This gives it around 200 km of range for each single charge and the battery also powers the elevated work platform.

In addition to the reduced carbon emissions, benefits of switching to an all-electric work platform truck are less noise, for the workers and residents in suburban areas, particularly when fixing network faults at night, and the absence of toxic diesel emissions during operation.

“SEA Electric are a Melbourne-based manufacturer of electric vehicles and leader in converting commercial vehicles from diesel to electric” said Jemena’s executive GM for electricity distribution, Shaun Reardon.

“The cherry picker was converted into an electric vehicle as part of a major reconstruction over a 12-month period.”

SEA Electric says the electric cherry picker is an industry first, and is already in service.

“It’s been a special and historical project for the management and engineering staff at SEA Electric to partner with Jemena in the development of this Australian-first 100 per cent electric Elevated Work Platform service truck,” said SEA Electric sales director for Australia and New Zealand Joe Di Santo.

“Not only is this electric powered cherry picker the first step in greening our fleet, it will also benefit our customers with a quieter operation and zero exhaust emissions,” said Reardon.

“We will look for new ways to further reduce the carbon emissions across our electricity network in the future.”

The addition of the truck to Jemena’s fleet follows just days after Jemena announced a deal with Hyundai to supply green hydrogen for the car maker’s hydrogen fuel cell vehicles.

Jemena is also implementing other sustainable measures including rolling out 500 LED ‘smart street lights’ that use up to 75 per cent less energy than traditional lighting. READ MORE

Article courtesy of The Drive, by Bridie Schmidt, August 13 2020

- Published in Articles, E-Range, Media Release, Mobile, Networking, News, SEA-Drive, Technology

Heavy EV keeps things cool and green

Foodstuffs and the Energy Efficiency and Conservation Authority (EECA) have partnered up to build New Zealand’s first electric powered refrigerated heavy duty truck.

From the tailgate to the engine and the fridge-freezer unit that sits on top, everything on the vehicle is powered by a battery.

It is the latest of several projects between Foodstuffs and EECA as they collaborate in the drive towards a carbon neutral New Zealand by 2050.

The full cost of the truck hasn’t been totalled yet, however EECA funded $400,000 towards the project which also included two other ambient trucks with all three now on the road.

It followed Foodstuffs’ successful application to the Low Emission Vehicles Contestable Fund for co-funding support.

Foodstuffs NZ sustainability manager Mike Sammons says it’s “a huge feat of Kiwi ingenuity”.

“We couldn’t purchase a fully electric refrigerated truck, because it didn’t exist, so we had the idea to custom build one,” he says.

With carbon emissions from transport currently at 18% in New Zealand, Sammons is optimistic this new innovation will have a role to play in transport carbon reduction.

“We’re 100% committed to playing our part in creating more sustainable transport solutions, building a fully electric refrigeration truck is a massive leap towards a carbon-free future for New Zealand,” he says.

Sammons says data on the truck will be collected over the next 12 months “to really get an understanding of the potential for electric trucks as a viable alternative to the status quo”.

EECA transport portfolio manager Richard Briggs says they could see the potential immediately.

“Heavy vehicles make up less than 5% of the national fleet, but are responsible for 29% of land transport emissions, so decarbonising the heavy fleet as much as possible will have a huge, positive impact.”

EECA had previously co-funded Foodstuffs to deliver 61 fast charge stations and 28 electric delivery vans.

“Foodstuffs has developed a great track record in this space, proving the viability of electrification,” Briggs says.

With EECA’s backing, Foodstuffs pulled together some of the country’s brightest and best transport, electrical and refrigeration engineers to convert the standard Isuzu FVY, 24 tonne, 6-wheel diesel truck to be 100% electric powered.

The electric truck will operate from the Foodstuffs distribution centre in Grenada, Wellington, under the stewardship of Foodstuffs North Island Transport.

Fleet and safety manager Blair Inglis played a big role in driving the project forward.

“We knew from the start building a fully electric EV truck would be a challenge and we had our fair share of them along the way, including COVID-19, but we always knew if we could pull it off, this innovation could set the direction for the future of commercial transport in New Zealand and that’s very exciting,” Inglis says.

After extensive testing and driver training, the electric truck recently set out on its first official delivery run to New World Miramar, a 60 km round trip.

With a range of between 150 and 200km and capable of transporting 14 pallets of product at temperatures as low as minus 15 degrees centigrade, the truck completed its inaugural journey with ease.

Foodstuffs North Island Transport driver Bagish Bansal gave the truck its first official run and says he “really liked it”.

“The ride was smooth, it was really quiet in the cab and it’s great to know that you’re helping the environment while doing your job, that feels really good. I really hope this is the shape of things to come for my occupation,” Bansal says.

Automotive technology company SEA Electric carried out the EV conversion on the Isuzu truck featuring its SEA-Drive 180 power system.

SEA Electric NZ general manager Stephen Fairweather says it’s the first heavy refrigerated truck that’s hit the road, however a smaller EV refrigerated truck for Countdown home delivery was the first project.

He says the company has been involved in a number of EV projects from waste collection, home delivery, daily freight and elevated work platform trucks.

“This vehicle’s requirements is certainly the largest refrigeration unit we’ve tackled in New Zealand, although it has been done prior in Australia. With the correct auxiliary equipment it is manageable,” Fairweather says.

“SEA Electric’s drive system is ideally suited to the metropolitan delivery model where this type of requirement comes into play. Being able to configure the SEA Drive system to customers usage, GVM and range requirements enables endless possibilities,” he says.

The company also worked closely with transport refrigeration specialist Thermo King and Fairweather says alignment between both parties is “critical” to getting the job done.

Earlier this year, New Zealand fishing company Sanford also unveiled an all-electric chilled van as part of its Auckland deliveries.

READ MORE, Article appeared in the July Issue of TransportTalk, by Nigel Moffiet, July 21 2020

- Published in Articles, E-Range, Media Release, Mobile, Networking, News, SEA-Drive, Technology

SEA ELECTRIC: CURRENT AFFAIRS IN ELECTRIC VEHICLES

There is a commercial electric vehicles future awaiting this country, the domestic elements of which will unfold over the coming years

Like a wave building beneath a surfboard, SEA Electric president Tony Fairweather is feeling a surge of momentum in his business and the commercial electric vehicle (CEV) sector in general.

With 272 units harbouring its SEA-Drive electric power system built or committed to since the company’s commercial inception in 2017, he foresees another three-figure year this year and will be looking for four figures by 2022.

It may be unwise to assume any hyperbole here, given the company now has a presence in Australia, New Zealand, the US, Thailand, South Africa and Israel.

And given that it is opening an office in Vienna and is looking to gain full European compliance green light by the second-half of this year.

And that SEA-Drives can now be found in a growing list presently comprising Isuzu, Hino, Iveco, Ford van, Mercedes-Benz and Dennis Eagle vehicles, the latter two for waste-trucks – while further afield, though still over limited distance, is a project in Mexico to test a Volvo VNR platform for urban semi duties hauling bread.

Not to mention that its November US order for 100 battery-electric Hino 195 light rigids counts as amongst the largest inked anywhere so far for such vehicles.

Also keeping the current running is the opportunity of exploiting a global power systems market estimated to be worth US$3 trillion (A$4.35 trillion) a year in 18 months to two years’ time and the market for converting relatively young diesel trucks to electric propulsion one estimated to be worth US$20 billion a year.

Plus the continuing development of battery performance, which, according to official US figures, has grown 56 per cent in the 30 months as cost measured in dollars per kilowatt hour has fallen from around US$1,000 (A$1,450) in 2008 to less than US$200 (A$290).

KIWI FOCUS

Even if some ATN readers retain doubts about the likely impact of CEVs on their businesses in their lifetimes, one New Zealand development last year should make them reassess – Alsco NZ’s trial of an aerodynamically bodied SEA-Drive 180-powered Hino GH 1828 to do a daily 286km trip taking in Rotorua-Tauranga and back in the morning, then Taupo and back in the afternoon.

Range – in this case, 200km, bolstered by depot recharging – will continue to be a critical factor in Australian operator thinking. And NZ operators, not unlike those in several other countries, have very focused and conditional financial support to at least come to terms with operational suitability – the Energy Efficiency and Conservation Authority (EECA) low emission vehicles contestable fund.

Gaining the support, which includes road-user charge savings, is crucial. Alsco NZ general manager finance Vanessa Atadeniz sees the total savings at half comparable diesel running costs.

Though the trial won’t wrap up until mid-year, Alsco group general manager NZ Mark Roberts reported in a company video in December: “The freighter seemed to provide and enticing financial case right from the outset.

“Not only will the shareholders be happy, it will greatly progress our own environmental goal to decrease our carbon footprint by 30 per cent before the year 2030.”

Alsco is also busy converting 15 diesel trucks to electric.

VIEW FROM DANDENONG SOUTH

Of course, there are challenges and challengers all around for SEA Electric but the latter are not the traditional names many might expect, those of the global original equipment makers (OEMs).

Asked to nominate its major competition, Fairweather names two US firms, Lightning Systems, the Colorado company powering vans and Ford and Chevrolet medium-duty trucks and buses, and Motiv Power Systems, which sells the Electric Powered Intelligent Chassis (EPIC) for light and medium truck and bus applications.

Which is understandable, as SEA isn’t doing business in the same space as OEMs, even if it works in the commercial vehicle market.

From SEA’s Dandenong South headquarters, the Australian firm sees its product in a strong position, with better performance and lower pricing than the opposition, and while not dismissive of the likes of the eCanter, believes it has that vehicle and similar covered, particularly on range.

“The challenge for OEMs is that they build engines and rely on services and parts,” Fairweather says.

“They have a lot of restructuring and repositioning to do.

“We provide a solution to them.”

He argues that while OEMs have spent heavily on national service and maintenance infrastructure, SEA is in a more nimble space, as vehicle simplicity and fewer moving parts make it more an in-depot proposition.

Rather than mechanics at dealer premises, SEA is developing a small corps of mobile aftersales engineers for more involved servicing.

It has eight globally; domestically there are two in Victoria, on in Sydney and one in Queensland, with plans recruitment in Perth, which now has three vehicles and another in New South Wales and more in Queensland for an expected Brisbane City Council order.

CUSTOMERS’ CUSTOMERS

ATN visited SEA’s headquarters hard on the heels of All Purpose Logistics taking on an electric truck to bolster its Ikea contract.

More on the All Purpose Transport EV launch, here

Indeed, Ikea and its emissionless delivery target of 2025 has proved a boon for SEA and a common denominator for deals with other transport providers, in Victoria’s Kings Transport and NSW’s ANC.

“Ikea came to us after introduction from Kings,” Fairweather says.

While it is an example of a ‘customer’s customer’ dynamic leading to an environmentally-based investment decision, he notes no other customer’s customer that SEA has is “at the same level as Ikea in mandating zero emissions”.

Still, the link is also promising as Ikea is also in Europe and the US – the US deal is at quote stage but Europe is less advanced at time of writing.

Kings was famously an early adopter. It now has three trucks and three vans but it is seen as transitioning from the early vehicles that are based on the FAW glider.

Of the ANC vehicles, SEA Electric reports they have travelled 85,000km, travelling an average of 185km per day on a single charge, and made more than 5,000 deliveries with an average weight of around 2.5 tonnes.

“It is estimated in 10 months the three ANC electric trucks have saved a total of 90 tonnes of CO2,” it says.

LOTS TO LIKE ON LOCAL LEVEL

While government support in Australia for CEV uptake is underdone at a federal level, interest is significant for SEA Electric’s vehicles at state and council levels.

And in its home state of Victoria, the government has been keen to see such enterprises progress in the wake of car-making’s demise.

While the October 2018 announcement of its Latrobe Valley van-building facility in Morwell came with much state government fanfare and support, it is sometimes overlooked that start date is some time in 2021.

The Latrobe Valley means cheaper land yet it is really quite close to Melbourne.

SEA Electric president Tony Fairweather notes some minor drift, a matter of couple of months, in the timing as the company continues to work on sourcing and purchasing suitable land and tweaking the agreement.

Fairweather points out that SEA is “very committed to regional areas” and that the company will run out of space in Dandenong South in early 2021 and the company very much needs to free up assembly space.

Latrobe Valley Authority (LVA) reports the company has a large back order for vehicles, and has employed five staff from Latrobe Valley who are working in their Dandenong facility while the Latrobe Valley operations get up and running.

The priority for the company is first to identify and secure a suitable site, and it will be working closely with local council to have this secured by the end of 2019.

SEA Electric has also started working with Federation Training to align the company’s skill requirements and course offerings.

Local government is an important sector with 11 units there, mostly vans, two buses and a tipper for the city of Yarra.

An indication of its importance is that SEA has a business development manager focused on it.

Fairweather believes state governments are in a position to smooth the path for CEVs without it costing a state anything.

“They could be a catalyst for early uptake,” he says.

For instance, this could be through allowing slightly heavier trucks to be driven on a car licence. Domestically this is at 4.5 tonne whereas elsewhere it’s six tonne.

“Uptake would be huge,” he says, though he admits there may be industrial relations issues attending such a move.

Or, given the payload issues with heavy batteries, allowing payload weigh to determine limits.

He is a fan of New Zealand’s approach, which is not an ongoing subsidy but financial support for one-off competitive projects that allow companies to test and trial to see if it’s suitable.

OEMS: A SYMBIOTIC RELATIONSHIP

How does SEA Electric’s relationship with the OEMs it supplies propulsion for work? The company gave ATN this insight into the process:

ADAPTION

A two-way non-disclosure agreements are signed.

Then 2D and/or 3D drawings of the cab/chassis platform are shared with the SEA engineering team.

Vehicle performance output objectives are agreed and documented.

The applicable SEA-Drive platform is presented in 2D, agreed with the OEM, and then all brackets, mounts, fixtures, etc. are drawn in 3D.

Weekly updates are provided to the OEM, with OEM engineering teams welcome to be actively involved in the development process.

A completely engineered and adapted SEA-Drive system is presented within three months to the OEM engineering executives for approval.

Software and control systems are revised to ensure the agreed performance outputs are achieved.

LOCALISATION/PROCUREMENT

This is facilitated towards the end of the ‘adaptation’ stage, with the SEA procurement team presenting to the OEM a range of components that can typically be fabricated or sourced locally.

SEA can provide resources to seek potential local suppliers and/or support the OEM in locating them.

Any components not able to be sourced locally can be procured directly from SEA and/or various global supplier options.

Once local options are identified, final drawings can be provided for quoting and ongoing supply.

The SEA procurement team will then introduce the OEM procurement team to our core global suppliers, so that relationships and accounts can be established, and direct procurement by the OEM can commence in the near future. At this time the first two completed SEA-Drive kits are purchased.

EXECUTION

Once the first two SEA-Drive kits have arrived at the OEM (in full) and the two glider donor chassis are presented and prepared for assembly, SEA will deploy two trainer technicians and a procurement specialist to the OEM.

Suitable prototype assembly and training facilities will be required, to ensure the time on site is optimised.

At completion of this stage, the OEM will have two fully operational and tested vehicles, trained fabricators, assemblers, engineers and procurement team.

A complete assembly and procurement manual will be provided, including new drawing numbers and suppliers.

The execution stage will typically be completed within four weeks, with all travel and accommodation costs borne by the OEM.

ONGOING SUPPORT

SEA provides 24/7 global telephone and online technical support, as well as a mobile technician for each volume deployment.

The technical team are available to visit the OEM at any time to assist with further developments or optimisation as required.

SEA says it is 100 per cent committed to the success of its OEM partners and the performance and support of its SEA-Drive technology.

Furthermore, its suppliers are also committed to success, evident by back-to-back warranty and 24/7 direct support. READ MORE

Article by Rob McKay, ATN – fullyloaded.com.au, 21.05.20

- Published in Articles, E-Range, Media Release, News, SEA-Drive, Technology

New EV truck helps tackle COVID-19

New Zealand-owned waste management and streetscape maintenance company Civic Contractors has introduced a new EV truck to carry out sanitation and street cleaning.

The 11-tonne truck picks up various-sized wheelie bins and washes them with hot water and steam, killing pathogens and bacteria (including COVID-19) and eliminating bad smells.

Its dual function pressure-washes and sanitises hard surfaces like city streets and pavements, using steam.

The truck is the first vehicle of its kind in New Zealand to use hot water rather than chemical agents for cleaning and sanitising and has a system for capturing dirty water to prevent it from entering local waterways.

The vehicle cost over $300,000 to design and build and was partially funded by a governmental Energy Efficiency and Conservation Authority (EECA) grant.

The 11-tonne truck is a SEA Electric EV cab and chassis with body and equipment built by Manco Engineering.

It’s based in Auckland and began operating on May 18 travelling around 200km or eight hours before it needs to be charged.

Limitations in current EV technology means it requires a small diesel unit to heat the water for the bin-washing equipment, but Civic says this is a short-term solution until technological gains are made in this area.

Compared to a diesel truck of this size, the reduction in carbon emissions is around 25 tonnes of CO2 per year.

“Hot-washing and steam cleaning is an effective solution for killing pathogens and bacteria that spread disease, but also that attract rodents and make the rubbish bins stink,” Civic Contractors managing director Bjorn Revfeim says.

“Now with the COVID-19 crisis, the issue of sanitisation of hard surfaces and bins has become more important than ever.”

“We’ve custom-designed the truck in the hope that New Zealand will take further steps to increase environmentally friendly waste collection services such as residential food waste collections, and eventually eliminate the need for single-use plastic bags in public streets and parks bins.

“Initially, we are going to get the truck working within our existing streetscape contracts – so, cleaning street bins and other street furniture and footpaths. In the future, we hope to see it being used at hospitals and medical clinics, food manufacturing and processing facilities, and any commercial businesses that are sensitive to organic waste material.“At this stage, we’re interested to hear from other businesses and industries that might be interested in trialling out our new machine,” Revfeim says. READ MORE

EV Talk, Nigel Moffiet, 18th May 2020

- Published in Articles, E-Range, Media Release, News, SEA-Drive, Technology

Drive a Practical Electric Truck

There has been plenty of hype in the media about the potential of electric trucks, but Diesel News went to see and drive a practical electric truck. It may not have all of the high-end super-high-tech of the the highly publicised trucks like Tesla or Nikola, but it does have some runs on the board.

The subject of electric trucks gets a lot of column inches in magazines and countless speculative stories on truck-related websites around the world. On reading the kind of stories being told, you might believe that the electric trucking nirvana is just around the corner, it isn’t.

This is new, complex and fast-developing technology, but there is a long way to go before it is the solution to all of our woes. The concept is a good one and powering a truck from an electricity grid using renewable energy does mean the drastic lowering of carbon emissions. The issues facing developers now is not a proof of concept one, but one of getting a concept up and running in a fleet and making money for its operator, having drivers drive a practical electric truck.

According SEA Electric, we are not there yet, but the company claims there is a clear road to a truck which will fulfil the brief of the future. SEA was a start-up company that came on the scene a few years ago and got a practical vehicle out there on the road and running. It is now in a phase of just getting the number of trucks it has built up and get those out onto the road and working.

There are a few operators buying electric vehicles, but in the main there are other factors at play in the purchasing decision. The truck in the All Purpose Transport fleet was chosen as a result of its client, Ikea, declaring an aim to go to zero emission deliveries. There is no government help at all for zero emission operators.

This does mean the take-up for electric trucks has been limited and the whole concept is quite slow in taking off. This doesn’t seem to deter Joe Di Santo, SEA Electric Sales Director ANZ, who works out of the SEA Electric headquarters in Dandenong in Victoria.

“What I have found is that, if you can get it right here, it’s very scalable,” says Joe. “It is so different here, more complex and more detailed. So, if you can get it working here, it is usually a good sign that it will work in the US and markets like that.

“Australia is a very different market for us. We are the only region that has a manufacturing plant, elsewhere in the world is more about licensing our technology. In the US we have licensing partners assembling the vehicles. We are working with Ford and had our first big order of 100 units.

“In our Australian operation, we are working towards our facility in the Latrobe Valley. That assembly plant transition is happening very smoothly, but it still not going to be available for another two years. In the meantime, we have our assemble facility in Dandenong, hopefully, that will be enough and become really efficient, but if there is more demand we may have go to a transitional facility until the Latrobe one opens.”

According to SEA, the plant in the Latrobe Valley will be a fully functioning assembly facility capable of producing 2,500 per year. At the same time there are a number of research projects in which SEA is working with truck, bus and van manufacturers.

There have already been trucks built using Isuzu, Hino and Iveco trucks, with the original power plant being replaced by an electric drive. These are under evaluation, either by the manufacturers themselves or with some of their customers.

These relationships look set to become more developed as the number of vehicles involved increase. This should see the current practice of removing the driveline before replacing it, being superseded by trucks being supplied from the assembly line as gliders, without the engines included. READ MORE

Diesel News, 16th April 2020

- Published in Articles, E-Range, Media Release, News, SEA-Drive, Technology

SEA Electric achieves patent milestone for truck tech

SEA Electric achieved another important milestone with the successful granting of the patent for its SEA-Drive® technology in Australia.

The ‘Management System for Commercial Electric Vehicles’ patent was granted on February 28, almost three years after the initial submission in April 2017.

The milestone is the culmination of many years of research, product development and system optimisation, said the Australian company.

With tens of thousands of miles of testing on SEA Electric’s generation 1 power-system technology, the now patented generation 2 power-system (known as SEA-Drive®), has proven performance, cost and weight outcomes as well as more than one million miles of collective performance validation data.

“Our overnight success has been almost a decade in the making and is a credit to the incredible team built by SEA Electric,” said SEA Electric’s Founder and President, Tony Fairweather.

“Australian Universities have recognised the importance of this automotive segment and have invested in producing some of the best electric vehicle engineering talent in the world.

“Our employees are practically, intellectually and emotionally invested in finding solutions to the real-world problems associated with hydrocarbon fuelled commercial vehicles.”

SEA Electric’s SEA-Drive® technology is patent pending in another 15 countries/regions, and it is expected further approvals like Australia’s will come into effect throughout 2020.

Glen Walker, Regional Director for SEA Electric’s Oceania Region added, “with the granting of this patent, SEA Electric further enhances its reputation as a Commercial Electric Vehicle innovator and disruptor. The SEA-Drive® technology is designed to exceed the unique performance requirements of commercial vehicles and it is a proven alternative power train to existing hydrocarbon fuelled solutions.

“SEA Electric is continuing to develop, enhance and deploy its electric SEA-Drive® technology in collaboration with like-minded OEM’s across a range of van and truck-based platforms in all major global markets.” READ MORE

Big Rigs, 9th Mar 2020

- Published in Articles, E-Range, Media Release, News, SEA-Drive, Technology

SEA Electric gains power system patent

Automotive technology company SEA Electric has been granted a patent for its SEA-Drive technology in Australia used in trucks and vans.

The ‘Management System for Commercial Electric Vehicles’ patent was granted on February 28 after an initial submission on April 18, 2017.

The milestone is the culmination of many years of research, product development and system optimisation, the Melbourne-based company says.

“Our overnight success has been almost a decade in the making and is a credit to the incredible team built by SEA Electric,” SEA Electric founder and president Tony Fairweather says.

“Australian Universities have recognised the importance of this automotive segment and have invested in producing some of the best electric vehicle engineering talent in the world.

“Our employees are practically, intellectually and emotionally invested in finding solutions to the real-world problems associated with hydrocarbon fuelled commercial vehicles.”

SEA Electric’s SEA-Drive technology is patent pending in another 15 countries/regions, and further approvals like Australia’s are expected come into effect throughout 2020.

“With the granting of this patent, SEA Electric further enhances its reputation as a commercial electric vehicle innovator and disruptor,” its Oceania regional director Glen Walker adds.

“SEA Electric is continuing to develop, enhance and deploy its electric SEA-Drive technology in collaboration with like-minded OEMs across a range of van and truck-based platforms in all major global markets.”

It’s also got a New Zealand base.

After tens of thousands of kilometres of testing on SEA Electric’s generation 1 power-system technology, the now patented generation 2 power-system (SEA-Drive), has proven performance, cost and weight outcomes as well as more than 1.6 million kilometres of collective performance validation data, the company says. READ MORE

EV Talk, Geoff Dobson March 3, 2020

About The Author

Geoff Dobson

Geoff Dobson is an ‘old-school journo’ thriving in a world of new technology. With 40-years of journalism experience already behind him, Geoff joined Auto Media Group three years ago to lead its EVtalk titles. A keen cyclist, he puts his Auckland commute to good use testing ebikes and scooters along the North Western cycleway.

- Published in Articles, E-Range, Media Release, News, SEA-Drive, Technology

Aussie SEA Electric granted patent for Commercial EV management system

SEA Electric make fully electric commercial vehicles and are quickly gaining international attention. While the sexy consumer battles of Tesla vs Porsche get plenty of headlines, the transition of commercial vehicles to electric powertrains is likely more difficult challenge and one Australians are not shying away from.

The Aussie company achieved another important milestone this week, with the successful granting of the patent for its SEA-Drive technology in Australia. The ‘Management System for Commercial Electric Vehicles’ patent was granted on the 28th of February 2020 after the initial submission on the 18th April 2017 (yep, our patent office works quickly).

The patent

The patent covers a management system for a commercial electric vehicle (EV), comprising:

- A controller area network (CAN) comprising a plurality of CAN buses connected to a plurality of components of the EV.

- A vehicle controller connected to the CAN and configured to monitor and/or control the plurality of components of the EV based on CAN signals.

Wherein the plurality of CAN buses and their respective components comprise:

- A drive CAN bus connected to a motor controller system comprising a motor controller connected to an electric motor.

- A battery CAN bus connected to a battery system comprising a high−voltage (HV) battery.

- A telematics CAN bus connected to a telematics system.

Wherein the vehicle controller is further configured to:

- Measure operating temperature of the motor controller and adjust the speed of a cooling pump and a radiator fan to maintain a predetermined operating temperature.

- Monitor a state of battery contactors of the HV battery and optimize an amount of time required to start the EV.

The milestone is the culmination of many years of research, product development and system optimization. This was reached after tens of thousands of miles of testing on SEA Electric’s generation 1 power-system technology, combined with the now patented generation 2 power-system, known as SEA-Drive.

The company now has more than a million miles of performance validation data to show it’s benefits of performance, cost and weight.

“Our overnight success has been almost a decade in the making and is a credit to the incredible team built by SEA Electric. Australian Universities have recognized the importance of this automotive segment and have invested in producing some of the best electric vehicle engineering talent in the world.

Our employees are practically, intellectually and emotionally invested in finding solutions to the real-world problems associated with hydrocarbon fueled commercial vehicles.”

SEA Electric’s Founder and President, Tony Fairweather reflects.

SEA Electric’s SEA-Drive technology is patent pending in another 15 countries/regions, and it is expected further approvals like Australia’s will come into effect throughout 2020.

“With the granting of this patent, SEA Electric further enhances its reputation as a Commercial Electric Vehicle innovator and disruptor. The SEA-Drive technology is designed to exceed the unique performance requirements of commercial vehicles and it is a proven alternative power train to existing hydrocarbon fueled solutions.

SEA Electric is continuing to develop, enhance and deploy its electric SEA-Drive technology in collaboration with like-minded OEM’s across a range of van and truck-based platforms in all major global markets.” Glen Walker, Regional Director for SEA Electric’s Oceania Region. READ MORE

Techau, Posted by Jason Cartwright on March 2, 2020

- Published in Articles, E-Range, Media Release, News, SEA-Drive, Technology, Uncategorized

SA’s First Electric Garbage Truck Doing The Rounds

What’s said to be South Australia’s first zero-emissions electric-powered kerbside garbage and recycling collection truck went into service in Adelaide last week.

The truck was supplied by Queensland-headquartered Superior Pak and uses drivetrain technology from Victoria’s SEA Electric, which is enjoying significant success with its commercial EV solutions both locally and overseas.

Zero emissions are great, but this truck is also expected to save East Waste a chunk of change.

“It is much more than a terrific environmental initiative by East Waste,” said General Manager Rob Gregory . “It will deliver financial gain to better manage the cost of kerbside collections of recyclable resources and waste.”

Valued at approximately $550,000, the EV cost $150,000 more than a diesel truck, but East Waste has conservatively projected it will save more than $220,000 over its seven year life compared to a diesel truck – so net savings of $70,000 or $10,000 a year. This is due in part to the difference in “fuel” costs, and maintenance costs reduced by at least two-thirds. East Waste points out the savings could be higher if the cost of diesel goes up and the truck lasts more than seven years, which is expected.

What’s Charging It?

Electricity used for recharging the truck is being offset by a 36kW solar power system at East Waste’s Ottaway depot. Details weren’t provided on how much energy the truck will consume over a typical day or whether the solar panels will generate equivalent to its requirements, but the solar system should crank out somewhere in the region of 56.8 megawatt-hours of electricity annually.

Even if the solar panels don’t cover all its energy use (and my guess is they won’t, making the zero emissions claim debatable), South Australia’s electricity supply is becoming increasingly cleaner – more than half of the state’s generation is from wind and solar energy.

Emissions reduction and financial savings aside, another advantage of using electric trucks for rubbish and recycling runs is they are much quieter. This means you’ll be able to hear the emptying of the neighbour’s recycling bin full of empty stubbies more clearly.

East Waste is a subsidiary of seven metropolitan Adelaide councils: the cities of Burnside, Campbelltown, Mitcham, Norwood, Payneham & St Peters and Prospect, the Town of Walkerville and Adelaide Hills Council.

Other Electric Waste Collection Trucks In Australia

Among other electric rubbish trucks in use across the country are Cleanaway’s “EVie” vehicles and a tipper truck used for hard rubbish collection by Victoria’s Yarra City Council.

Another electric recycling truck featuring SEA electric drivetrain technology, this one for SUEZ in Western Australia, has a 230kWh battery providing more than 200 kilometre driving range before recharge – but there’s lots of stopping and starting with this sort of activity. SEA Electric says it will be capable of 1,200 bin lifts a day.

SolarQuotes Blog, February 25,2020 by Michael Bloch

- Published in Articles, E-Range, Media Release, Mobile, Networking, News, SEA-Drive, Technology

ContainerCo puts NZ’s largest EV on the road

New Zealand’s largest electric heavy vehicle (eHV) is on the road moving containers between port and rail facilities in Auckland.

Container hire and sales business ContainerCo, with support from Energy Efficiency Conservation Authority (EECA), has introduced the Isuzu truck featuring Sea Electric technology.

It can carry three 20-foot containers which is up to the maximum size allowed on New Zealand roads without a permit.

ContainerCo managing Ken Harris says the electric truck marks an important step in reducing air and noise emissions.

“We operate our container hire, sales and services businesses from sites right around the country and the ability to silently and cleanly move containers to and from rail and ports in urban environments is a big step forward,” Harris says.

“We can see a lot more units in our fleet in the future as well as EV’s replacing diesel powered forklifts inside our facilities quite soon.”

ContainerCo worked in a funding partnership with the EECA, receiving $99,700 to identify an energy efficient electric truck of the right size with the ability to operate up to 15 hours before recharging.

“We are excited to welcome the first electric truck to our fleet, in partnership with EECA. It is the first step of an ambitious long term programme to prove the viability and desirability of transforming our fleet of handling and transport equipment to EV.

“ContainerCo operates facilities that handle hundreds of thousands of shipping containers around the country and with innovation we can electrify a wide range of our vehicles including forklifts, cranes, and support vehicles.

“We expect this new truck to demonstrate the opportunity to reduce environmental impacts and improve the efficiency.

“EECA’s advice and support enabled us to take this first step. More eHVs will be added to the fleet and introduced to other regions as we build experience and the charging network expands,” Harris says. READ MORE

EV Talk, Nigel Moffiet, Nov 14, 2019

About The Author

Nigel Moffiet

Nigel Moffiet joined TransportTalk as editor in 2017. He has a strong interest in the transport industry and brings nearly 10 years of journalism experience. Before taking the helm at TransportTalk, he was with Fairfax Media covering everything from local government, education, housing and the environment.

- Published in Articles, E-Range, Media Release, News, SEA-Drive, Technology

- 1

- 2